We’re very proud and honoured to be asked to share our knowledge and experience with CAD/CAM and implant restorations for both the ADi and Atlantis Isus.

The upcoming dates are :-

Location – Birmingham

Speakers – Dr Tim Doswell – Steve Campbell

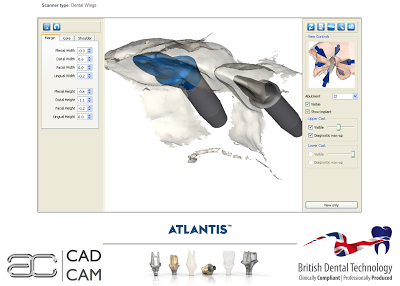

Date – 19th September – Atlantis Isus – A guide to using the system for surgeons & technicians

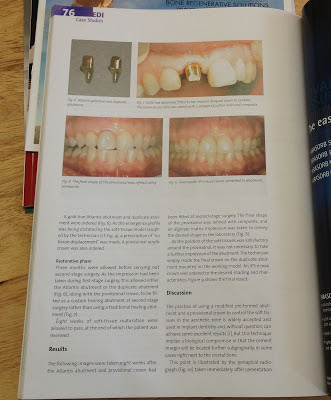

Tim & Steve will demonstrate the unique clinical and cost effective advantages offered by using a premium CAD/CAM partner compared with the old, inconsistent and expensive cast methods used to fabricate multi unit screw retained implant restorations.

Venue

Hotel La Tour, Albert Street, Birmingham, B5 5JE

Registration, refreshments & buffet are available from 6.30pm ready to start at 7.00pm

Location – London Stansted Airport

Speaker – Steve Campbell

Date – 24th October – ADi Essex/Herts Study Club – Restoring Dental Implants – What’s New?

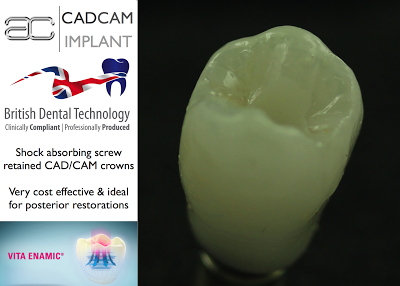

Steve will outline the latest developments in CAD/CAM technology for the fabrication of custom abutments and screw retained implant restorations, along with looking at some new materials and techniques that offer us advantages over the traditional porcelains and acrylics that we sometimes use to restore implant restorations.

We will also see how these new solutions are often vastly more cost effective than what we have on offer with traditional restorative materials we have had in the past

Venue

Radisson Blu Hotel London Stansted Airport, Waltham Close, London Stansted Airport, Essex, CM24 1PP

Registration, refreshments & buffet are available from 7.00pm ready to start at 7.30pm

Location – Belfast

Speaker – Steve Campbell

Date – 14th November – ADi Belfast Study Club – Restoring Dental Implants – What’s New?

Steve will outline the latest developments in CAD/CAM technology for the fabrication of custom abutments and screw retained implant restorations, along with looking at some new materials and techniques that offer us advantages over the traditional porcelains and acrylics that we sometimes use to restore implant restorations.

We will also see how these new solutions are often vastly more cost effective than what we have on offer with traditional restorative materials we have had in the past

Venue

The Ramada Hotel, Shaws Bridge, Belfast, Ireland, BT8 7XP

Registration, refreshments & buffet are available from 7.00pm ready to start at 7.30pm

Location – Warwickshire

Speaker – Steve Campbell

Date – 20th November – ADi Warwick Study Club – Restoring Dental Implants – What’s New?

Steve will outline the latest developments in CAD/CAM technology for the fabrication of custom abutments and screw retained implant restorations, along with looking at some new materials and techniques that offer us advantages over the traditional porcelains and acrylics that we sometimes use to restore implant restorations.

We will also see how these new solutions are often vastly more cost effective than what we have on offer with traditional restorative materials we have had in the past

Venue

Hilton Warwick, Junction 15, M40, A429 Stratford Road, Warwickshire, CV34 6RE

Registration, refreshments & buffet are available from 7.00pm ready to start at 7.30pm

Location – Edinburgh

Speakers – Dr Tim Doswell – Steve Campbell

Date – 28th November – Atlantis Isus – A guide to using the system for surgeons & technicians

Tim & Steve will demonstrate the unique clinical and cost effective advantages offered by using a premium CAD/CAM partner compared with the old, inconsistent and expensive cast methods used to fabricate multi unit screw retained implant restorations.

Venue

Edinburgh Dakota Hotel, 11 Ferrymuir Retail Park, South Queensferry, EH30 9QZ

Registration, refreshments & buffet are available from 6.30pm ready to start at 7.00pm

Booking

To book for any ADi Study Club you can either visit the website www.adi.org.uk and book

or call the office, 020 8487 5555, or email info@adi.org.uk

To Book for any of the Atlantis Isus dates please contact Gill Hallet on 01453 793273

or email gill.hallett@dentsply.com